Roller Follower Malfunction Causes, Symptoms, Precaution and Solution

The Roller Follower Malfunction in Marine engine and the potential consequences of their malfunction. It outlines the causes, symptoms, and detrimental effects of roller follower failures, including engine damage and reduced efficiency. Furthermore, the blog emphasizes the importance of routine maintenance, quality components, and monitoring systems as preventive measures, alongside troubleshooting actions to diagnose and address issues effectively.

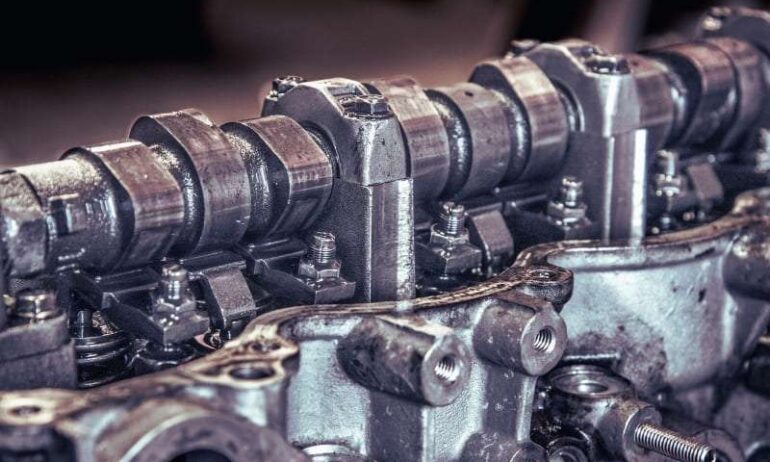

What is Roller Follower Malfunction?

The roller follower malfunction refers to a failure in the roller follower mechanism of an engine, which plays a crucial role in the actuation of valves. This malfunction can lead to irregular opening and closing of the valves, impacting engine performance, efficiency, and longevity. In marine engines, where reliability is paramount, any failure in this system demands immediate attention.

Significance of Roller Follower:

The roller followers in marine engines, especially in high-speed or medium-speed engines, are essential for the precise timing of valve operations. A malfunction here can result in significant performance loss, increased fuel consumption, and even catastrophic engine failure, making it a critical focus area for operators and maintenance teams in sectors like marine, oil & gas, and power generation.

Components Involved & Their Role:

- Key components related to the roller follower mechanism include:

Roller Follower: Transfers motion from the camshaft to the engine valves, ensuring proper timing and actuation.

Camshaft: Drives the roller follower and dictates the timing and duration of valve openings.

Valves: Control the intake of air and the exhaust of gases, directly impacting the engine’s operational efficiency.

Push Rods: Assist in transferring motion from the roller follower to the valves.

Bearings: Support the moving components and allow for smooth operation.

Conditions That Lead to This Issue:

High Loads and Stress: Excessive stress on the engine due to overload conditions can lead to deformation in components affecting the roller follower assembly.

Improper Lubrication: Insufficient lubrication can cause increased friction, leading to rapid wear and eventual failure.

High Operating Temperatures: Extreme temperatures can cause thermal expansion and alter the mechanical properties of materials.

Contaminated Engine Oil: Particles and impurities in oil can cause abrasion and damage to the follower mechanism.

Misalignment: Incorrect installation or wear can lead to misalignment of components, thus impairing functionality.

What Would Cause the Roller Follower Malfunction?

Fatigue: Prolonged wear and tear on the followers can lead to fatigue failure.

Improper Installation: Poorly installed components can directly affect the functionality of the roller followers.

Material Defects: Flaws in the materials used in the roller follower can lead to premature failure.

Poor Maintenance Practices: Inadequate checks and maintenance can cause unnoticed degradation.

Excessive Engine Vibration: Vibration can loosen components and misalign the roller follower mechanism.

Symptoms/Signs of the Roller Follower Malfunction

Key observable signs of roller follower malfunction include:

Engine Misfiring: Irregular combustion due to valve timing issues.

Increased Noise: Unusual tapping or knocking sounds from the valve train area.

Loss of Power: Noticeable drop in engine performance and efficiency.

Oil Pressure Fluctuations: Changes in oil pressure readings can indicate problems in lubrication.

High Exhaust Emissions: Increased emissions due to improper valve sealing.

Consequences of the Roller Follower Malfunction

The potential consequences of roller follower malfunction include:

Reduced Engine Efficiency: Increased fuel consumption and decreased power output.

Valve Damage: Continuous misalignment can lead to bent or worn valves.

Increased Maintenance Costs: Higher frequency of repairs and part replacements.

Engine Seizure: In extreme cases, a complete failure of the engine can occur due to critical internal damage.

Damaged Bearings: Excess wear on bearings can lead to significant costs and repairs.

Troubleshooting and Actions to Be Taken in Case of the roller follower malfunction

Troubleshooting steps include:

Conduct Visual Inspections: Check for any signs of wear or damage on components.

Check for Unusual Noises: Listen for abnormal noises while the engine runs.

Monitor Oil Pressure: Keep track of any fluctuations that may indicate issues.

Inspect Valve Timing: Use timing tools to ensure valves are functioning correctly.

Conduct a Vibration Analysis: Measure engine vibrations to diagnose potential misalignments.

Solution for Roller Follower Malfunction

1. Isolate the Issue through Inspections and Diagnostics: Conduct thorough inspections and use diagnostic tools to pinpoint the exact cause of the roller follower malfunction. Our thorough inspection services are designed to detect early signs of wear and tear. When repairs are required, we offer professional Marine Engine Overhaul Services to restore peak performance. Furthermore, we provide high-quality Marine Engine Spares to replace outdated components, ensuring your engine continues to run smoothly and reliably.

2. Replace Worn or Damaged Components Promptly: If any roller follower or associated parts are found to be worn or damaged, replace them immediately. Delaying replacements can affect engine performance and cause further mechanical issues.

3. Ensure Proper Alignment and Lubrication: Check the alignment of the roller follower and ensure proper lubrication is applied. Misalignment or insufficient lubrication can lead to increased wear and further malfunctions.

4. Implement a Robust Maintenance Plan: Establish a consistent and comprehensive maintenance plan for regular checks on the roller follower and related components. Preventive maintenance reduces the risk of future malfunctions and enhances the engine’s longevity.

Precautionary Measures for Addresing Roller Follower Malfunction

To mitigate the risk of roller follower malfunction:

Regular Maintenance: Schedule consistent engine check-ups to monitor performance.

Quality Lubrication: Use high-quality lubricants and ensure adequate oil levels. To extend the life of lube oil and maintain its quality, our advanced Oil Quality Management Solution with an Oil Filtration System and Oil Condition Monitoring can help you with it.

Monitor Operating Conditions: Keep track of engine loads and temperatures.

Inspect Components: Routinely check the roller follower and related components for any signs of wear.

Proper Training: Ensure engine operators are trained to recognize symptoms early.

Remote Monitoring: Leverage advanced remote condition monitoring technology to track bearing performance and identify early indicators of potential issues. Our cutting-edge Engine Condition Monitoring System, Vib360, is specifically crafted to detect engine problems at their earliest stages, helping to minimize maintenance expenses and avoid costly breakdowns.