VIB360 Engine Condition Monitoring System

Stay miles ahead of potential engine failures to Ensure Optimal Fleet Performance

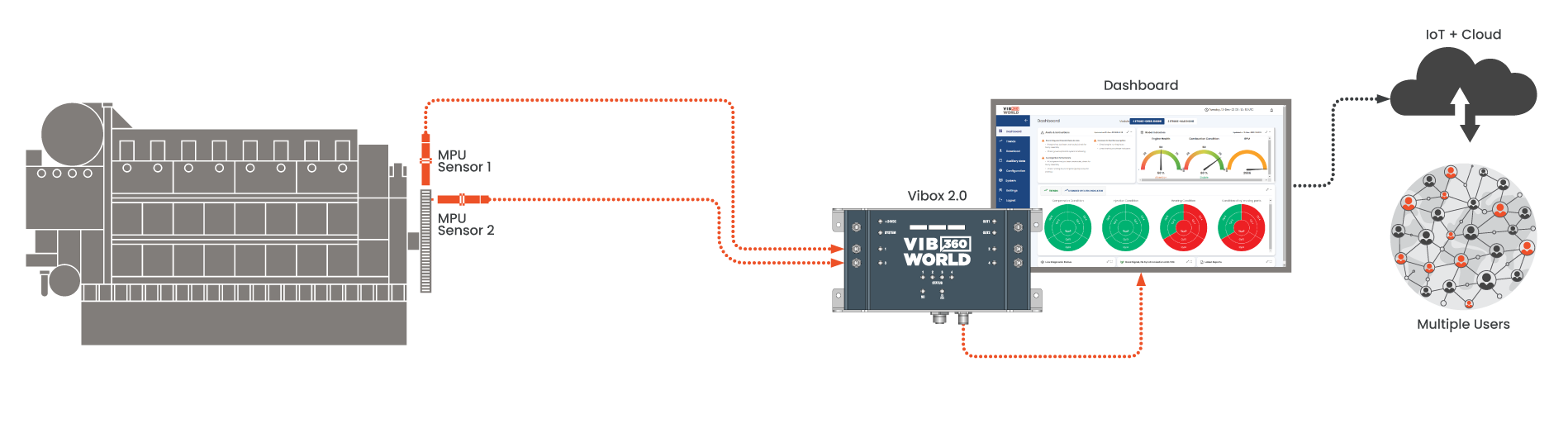

The Vib360 Engine Condition Monitoring System revolutionizes maritime operations by offering unparalleled insight into engine health. With just two non-intrusive sensors, you’ll gain real-time visibility into emerging defects, enabling proactive maintenance and minimizing costly downtime. This advanced solution is designed for simplicity, allowing for easy installation on engines of any make or model with six or more cylinders.

Prevent Unplanned Breakdowns

Optimize Maintenance Scope

Reduce Fuel Consumption and Emissions

Enhance Engine Reliability

Class Approved Extension on Engine MTBO

Reduce Cost of Maintenance

By continuously monitoring machinery health, Vib360 empowers you to address potential issues swiftly, ensuring optimal performance and longevity of your fleet’s engines. The system’s remote monitoring capabilities consolidate data from all assets under a single command, streamlining oversight and control. With Vib360, you’re not just monitoring engines; you’re safeguarding your entire operation, reducing maintenance costs, and maximizing vessel uptime. Experience the peace of mind that comes with knowing your engines are under constant, intelligent surveillance, allowing you to focus on what matters most – running a successful business.

Install Vib360 ECMS to Overcome Following Challenges You Face Today

Logistics and Supply Chain Issues for Spare Parts & Manpower: Plan engine maintenance well in advance, minimizing delays caused by supply chain disruptions or workforce availability.

Unnecessary Spare Part Replacements Due to Time-Based Maintenance: Transition to condition-based maintenance by identifying the exact state of your engine. Replace only the components that truly require attention, significantly reducing spare part usage and costs.

Reliance on Certified Experts to Interpret Results: Simplified, user-friendly interface with clear alert notifications and actionable steps eliminates the dependency on specialized expertise for result interpretation.

Human Errors Leading to Operational Inefficiencies: Leverage highly accurate, real-time monitoring to eliminate inefficiencies caused by human error during maintenance or diagnostics.

Monitoring Engines of Different Makes and Models: Access real-time health insights for all engines in your fleet, regardless of make or model, ensuring comprehensive and uniform monitoring.

Features of Vib360 Engine Condition Monitoring

Early Detection of Engine Defects

The system works tirelessly to identify emerging defects in your engine components. This proactive approach allows you to address issues before they escalate into major problems, saving you significant time and money on repairs.

FAQ's

-

How does Vib360 Engine Condition Monitoring reduce maintenance costs?By detecting emerging defects early, Vib360 allows for proactive maintenance, preventing minor issues from escalating into major, costly repairs. This approach can significantly reduce overall maintenance expenses and unexpected downtime.

-

In what ways does Vib360 Engine Condition Monitoring help lower emissions?Vib360 helps reduce emissions by maintaining engine performance at its peak efficiency. By enabling early detection of engine defects and transitioning to condition-based maintenance, the system ensures that engines operate optimally, avoiding incomplete combustion and reducing pollutant emissions.

-

How does Vib360 Engine Condition Monitoring extend engine life?By identifying defects early and enabling condition-based maintenance, Vib360 prevents unnecessary wear and major failures. This proactive approach ensures optimal engine performance and extends component longevity.

-

What benefits do ship operators gain from Vib360 Engine Condition Monitoring being class approved?Class approval ensures Vib360 meets industry standards for safety, reliability, and performance, giving ship operators confidence in its use. It simplifies regulatory compliance, enhances fleet credibility, and ensures seamless integration. Installing a class-approved system also reduces operational risks and improves vessel marketability.

-

How does obtaining a SmartShip Notation benefit ship operators?SmartShip notation by ABS recognizes vessels equipped with advanced systems for data collection, monitoring, and decision-making. SmartShip status enhances operational efficiency, ensures compliance with emerging maritime standards, and strengthens the vessel's marketability.

-

How can Vib360 Engine Condition Monitoring improve engine maintenance efficiency?It can help you enable condition-based maintenance, reducing downtime and costs. It offers real-time health data, remote fleet monitoring, and centralized insights, simplifying planning and minimizing human errors.

-

If OEMs require time-based maintenance, what added value does Vib360 Engine Condition Monitoring provide?It complements time-based maintenance by detecting defects between intervals, providing real-time health data, and justifying optimized schedules with evidence, ensuring proactive and cost-effective maintenance.

Experience our Vib360 Dashboard

Vib360 Engine Condition Monitoring System Type Approved by ABS & IR Class

Here is What it Means For You:

- 1. Asset owners can follow more effective condition-based maintenance rather than OEM-recommended time-based maintenance

- 2. The ABS & IRS certified system helps in extending the major overhauls

- 3. The solution can guide minor overhauls to avoid catastrophic failure and to increase fuel efficiency

- 4. Assets monitored with a class-approved system have a good resale value