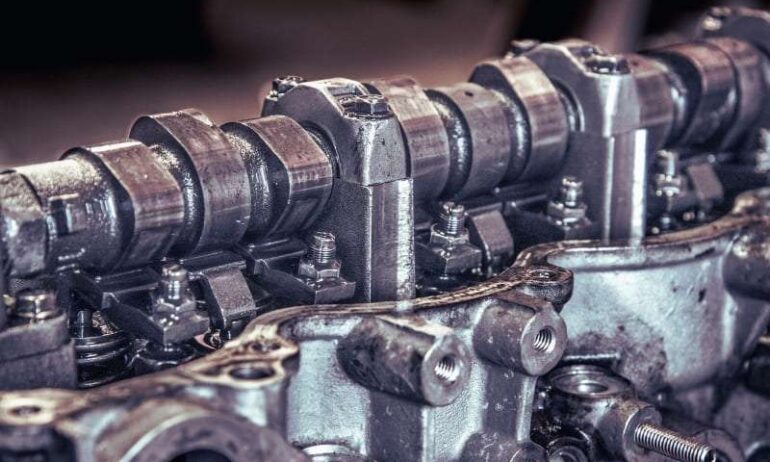

Camshaft Lobe Defect Causes, Symptoms, Precaution and Solution

Camshaft Lobe Defect in Marine Engines which provides a comprehensive overview of camshaft lobe defects, emphasizing their impact on engine performance in marine applications. It discusses the critical roles of the camshaft and its associated components, the causes and symptoms of these defects, and the potential consequences, including engine failure and increased emissions.

What is a Camshaft Lobe Defect?

The Camshaft Lobe Defect refers to an abnormality or wear in the camshaft lobe— the part of the camshaft that interacts with the engine’s valves. This defect can lead to improper valve timing and function, negatively affecting engine performance and efficiency. In marine engines, where reliability is paramount, this issue takes on significant importance.

Criticality Camshaft Lobe:

The camshaft lobe is a critical component in any engine, providing the motion necessary to open and close valves in synchronization with the engine cycle. Any defect can lead to misalignment, affecting combustion efficiency, emissions, and overall engine performance.

Components Involved & Their Role:

- Camshaft: Converts rotational motion into linear motion to operate the engine’s valves.

- Valves: Open and close at precise timings to allow fuel-air mixture to enter and exhaust gases to exit the engine.

- Timing Belt/Chain: Connects the crankshaft and camshaft, ensuring optimal synchronization.

- Engine Block: Houses the camshaft and maintains alignment with other components.

Conditions That Lead to This Camshaft Lobe Defect:

Several conditions can contribute to camshaft lobe defects, particularly in high-speed or medium-speed marine engines:

Poor Lubrication: Insufficient oil can lead to increased friction and accelerated wear.

Overloading: Strain from excessive loads can misalign components.

Corrosive Environment: Saltwater and humidity in marine applications can lead to oxidation and material degradation.

Manufacturing Defects: Faulty materials or machining can predispose lobes to failure.

What Would Cause the Camshaft Lobe Defect?

Potential causes of camshaft lobe defects can include:

Insufficient Lubricant Supply: Low oil levels can compromise lubrication.

Contaminated Oil: Dirt or particles can cause abrasion.

Incorrect Engine Timing: Sparse adjustments can lead to mis operation.

Ageing and Wear: Natural wear from prolonged use can accumulate over time.

Symptoms/Signs of the Camshaft Lobe Defect

Observable signs of camshaft lobe defects may include:

Loss of Power: Reduced engine performance due to valve malfunction.

Rough Idle: Unstable engine operation at low RPMs.

Increased Emissions: Poor combustion due to misfiring valves.

Unusual Noises: Clicking or tapping sounds from the engine due to abnormal wear.

Consequences of the Camshaft Lobe Defect

The potential consequences of camshaft lobe defects can be severe and encompass:

Reduced Engine Efficiency: Poor combustion leading to higher fuel consumption.

Complete Engine Failure: Severe issues may lead to catastrophic engine breakdown.

Increased Maintenance Costs: Frequent repairs and component replacements are necessary for proper functionality.

Affected components can include:

Valves: Poorly functioning valves can lead to inefficient combustion.

Timing Mechanism: Components might fail due to misalignment with the camshaft.

Lifters: Increased wear and failure can occur in the lifters.

Troubleshooting and Actions to Be Taken in Case of the Camshaft Lobe Defect

Troubleshooting should follow these steps:

Visual Inspection: Check for visible signs of wear or damage on the camshaft.

Oil Analysis: Examine oil for contamination or degradation.

Timing Alignment Check: Use tools to ensure proper timing alignment.

Replacement Assessment: Determine if the camshaft or affected components require replacements.

Solution for Camshaft Lobe Defect

1. Thorough Inspections: Regular inspections of the camshaft and related components are essential for identifying early signs of wear or damage. This helps detect potential issues before they lead to major failures and ensures the engine operates smoothly. Our comprehensive inspection services help identify signs of wear and tear early. In cases where repairs are needed, we provide expert Marine Engine Repair solutions to restore functionality

2. Prompt Replacements: If a camshaft lobe defect is detected, it is crucial to replace the damaged camshaft or its components immediately. Delaying replacements can cause further damage to the engine, leading to costly repairs and downtime.Additionally, we supply genuine Auxiliary Engine Spares to replace worn-out components, ensuring optimal performance and reliability

3. Adherence to Maintenance Schedules: Following the manufacturer’s recommended maintenance schedule is key to preventing camshaft lobe defects. Regular servicing and upkeep ensure that the engine remains in optimal condition and that wear is minimized

4. Ensure Proper Engine Operation: Ensuring that the engine operates within its designed parameters, including correct temperature, load, and speed, reduces stress on the camshaft and other components. Proper engine operation helps prevent undue wear on the camshaft lobes.

Precautionary Measures For Addressing Camshaft Lobe Defect

- Regular Maintenance: Frequent checks can prevent undetected issues.

- Using Quality Lubricants: High-quality oils reduce wear.

- Monitoring Engine Loads: Avoiding excessive loads ensures stability.

- Routine Oil Changes: Frequent changes prevent oil contamination. Our advanced Oil Quality Management Solution, which includes an Oil Filtration System and Oil Condition Monitoring, is specifically created to extend the lifespan of lubrication oil and maintain its superior quality.

- Remote Monitoring: Leverage advanced remote condition monitoring technology to track bearing performance and detect potential issues at the earliest stage. Our cutting-edge Engine Condition Monitoring System, Vib360, is specifically crafted to identify engine problems early, minimizing maintenance costs and preventing expensive breakdowns.