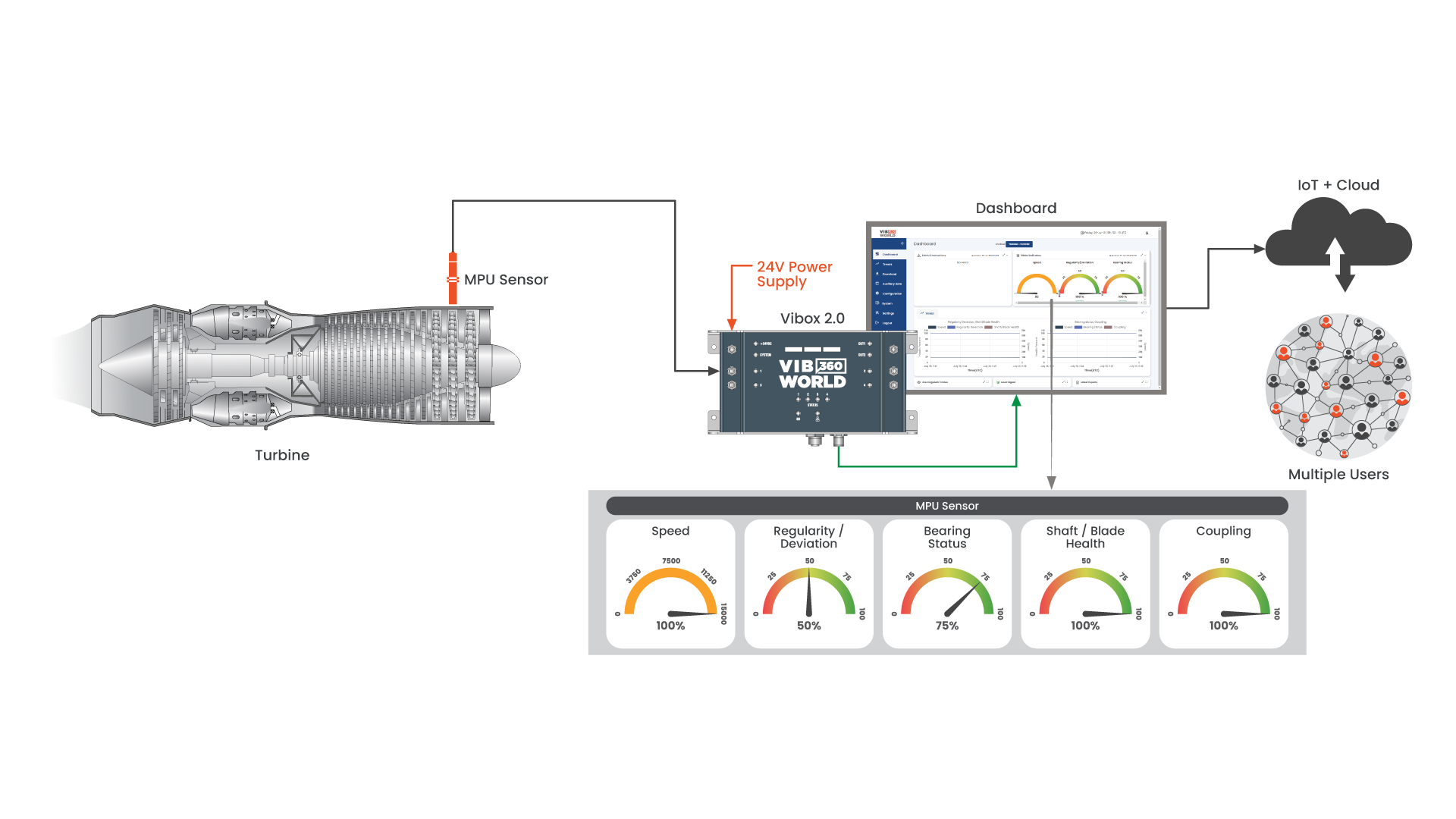

Vib360 Gas Turbine Condition Monitoring System

Maximize Turbine Efficiency with Precision Monitoring and real-time actionable insights

Eliminate Breakdown

Prioritize Maintenance Basis current Requirement

Plan Maintenance in Advance

Reduce Scope of Maintenance Basis Data

Extend Turbine Life

Gas turbine condition monitoring has entered a new era of simplicity and precision with the Vib360 Gas Turbine Condition Monitoring System. This revolutionary single-sensor solution uses advanced torsional vibration analysis to provide comprehensive insight into your turbine’s health without the complexity and cost of traditional multi-sensor installations. By detecting microscopic changes in rotordynamics during operation, you can spot emerging issues weeks or even months before traditional methods raise any alerts. This non-intrusive monitoring approach captures subtle mechanical changes in real-time, enabling early detection of potential problems before they develop into costly issues.

In an industry where every degree of efficiency matters and downtime costs millions, the Vib360 system transforms complex vibration patterns into clear, actionable intelligence. It’s like giving your turbine a voice to tell you exactly what it needs, allowing you to eliminate breakdowns, prioritize maintenance based on current requirements, plan maintenance better, reduce the scope of maintenance based on data, and extend the life of your valuable assets.

Features of our Gas Turbine Monitoring System

Real-Time Turbine Health Insights

Vib360’s Gas Turbine Condition monitoring system delivers continuous, real-time insights into your gas turbine’s health. By analyzing torsional vibration patterns, it identifies potential issues instantly, enabling quick, informed decisions. Optimize performance, reduce downtime, and extend turbine life with real-time data at your fingertips.

Insights From Vib360 Gas Turbine Condition Monitoring System

Regularity/Deviation-Indicates issues in the steam intake system or the lubrication system.

Bearing Status – Indicates condition of bearings due to coupling malfunction, structure/support bending, excessive dynamic gearmesh force, bearing wear, cylinder defect (bore/bearing shell), stator geometry defect, friction (dynamic seal defects), and axial stability between the thrust bearings.

Shaft/blades health – Indicates overall health of Shaft/Blade and any deterioration due to Loss of clamping, dynamic instabilities, damage to rotating/ or fixed blades

Combustion Kit – This indicator expresses the fatigue during operation of the coupling during each cycle. It also describes a variable dynamic misalignment (isokinetic defect) between the turbine and the coupled element of the shaft line

Experience our Vib360 Dashboard

FAQ's

-

Is special training required to use the Vib360 system?The Vib360 system features a user-friendly dashboard designed for ease of use. While we provide training to help you get the most out of the system, extensive specialized knowledge is not required.

-

How often does the Vib360 Gas Turbine Condition Monitoring System update its data?The Vib360 system provides real-time monitoring, continuously updating data to give you the most current information about your turbine's health.

-

Can the Vib360 Gas Turbine Condition Monitoring system integrate with our existing monitoring systems?Yes, the Vib360 system is designed to complement and enhance your existing monitoring setup. We can work with you to ensure seamless integration.

-

What kind of support do you offer after installation?We provide ongoing support and continuously update our algorithms based on the latest industry insights. Our team of experts is always available to help you maximize the benefits of your Vib360 system.

-

How Do I Know if the Vib360 Gas Turbine Condition Monitoring System?The Vib360 Gas Turbine Monitoring System is turbine-agnostic, meaning it can be installed on any gas turbine regardless of size or manufacturer.