Prediction of Torsional Vibration Damper Anomaly During PoC Operation

Customer Profile

- Customer: Operator of an ocean-going commercial vessel

- Asset: Auxiliary Engine

- Auxiliary Engine Make: Hyundai-Himsen H21/32

- Rated Power: 1170 kW @ 900 RPM

- Operating Hours: ~ In excess to 35,000

- Industry: Marine – Commercial Shipping

Context

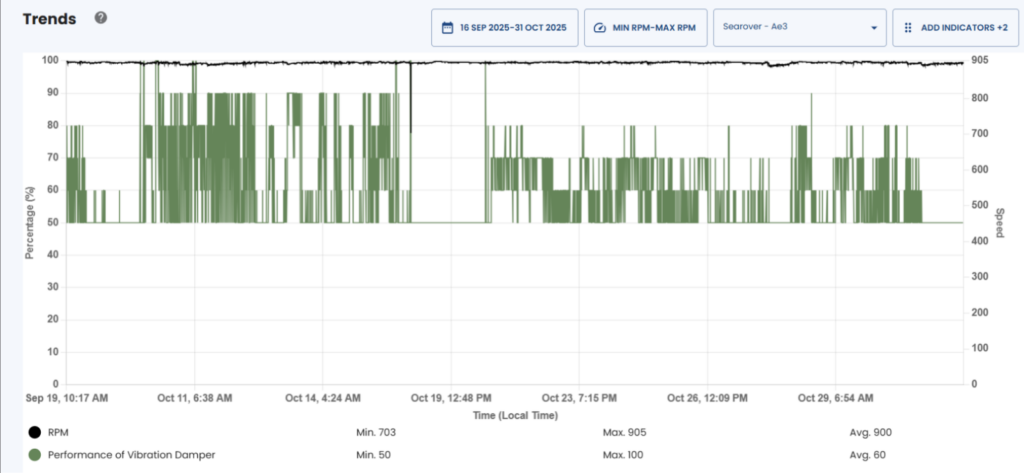

Vib360 was installed on the vessel as a Proof of Concept (PoC) during normal commercial operation, with the objective of evaluating its suitability for continuous engine condition monitoring.

During routine daily use of the system, Vib360 identified a progressive change in torsional behaviour, despite the absence of alarms or performance complaints.

At the time the anomaly was raised:

- No OEM alarms were active

- Engine load and speed were stable

- Engine operation was considered normal by ship staff

The indication was therefore system-initiated and not triggered by any reported fault.

Problem Statement

Torsional vibration dampers are critical for controlling cyclic torsional energy in the crankshaft system.

Degradation of damper effectiveness typically progresses internally and is difficult to detect through conventional vibration, temperature, or alarm-based monitoring.

Undetected damper degradation can lead to increased torsional stress on the crankshaft, couplings, and gear train.

Objective of Vib360 Assessment

- Detect early-stage degradation of torsional vibration damping

- Identify physics-based indicators prior to functional failure

- Support condition-based maintenance planning

Measurement Setup

- Flywheel-mounted Magnetic Pickup Unit (MPU)

- One cylinder peak pressure sensor used as a reference sensor

- Comparative analysis at similar load and operating conditions over time

Physics-Based Findings

Vib360 analysis showed:

- Progressive increase in firing-order torsional harmonic amplitudes

- Reduced attenuation of torsional energy across operating cycles

- Changes in harmonic phase and energy distribution consistent with reduced damping effectiveness

These signatures were repeatable and independent of external load variation.

Mechanical / Operational Interpretation

A healthy torsional vibration damper dissipates cyclic torsional energy and limits transmission into the crankshaft system.

The observed harmonic behaviour indicated a reduction in effective damping capacity, consistent with internal damper degradation.

The patterns were not consistent with combustion imbalance or load variation.

Action Taken

- Planned inspection of the torsional vibration damper during a scheduled maintenance window

- Replacement of the damper based on Vib360 indication

Outcome and Value

- Damper degradation addressed before secondary damage occurred

- Avoided risk of crankshaft and gear train fatigue

- Maintenance executed in a controlled, planned manner

- Post-replacement Vib360 data showed restoration of normal torsional behaviour

Technical Significance

This case demonstrates Vib360’s ability to identify early-stage torsional vibration damper degradation through physics-based harmonic analysis, supporting CBM-aligned maintenance decisions.