Excessive Main Bearing Clearance Causes, Signs, Precaution and Solution

The topic covers excessive main bearing clearance, its causes, criticality, and consequences on engine performance, highlighting the role of proper maintenance and lubrication in preventing issues. It also provides solutions, troubleshooting steps, and precautionary measures, emphasizing the importance of expertise and monitoring systems to ensure engine reliability and longevity.

What is excessive main bearing clearance?

Excessive main bearing clearance occurs when the gap between the main bearings and the crankshaft journal exceeds the manufacturer’s specified limits. This condition can lead to a variety of engine performance issues, including increased friction, heat, and potential failure of the engine components. For example, if the gaps are too wide, it can cause the crankshaft to ‘wobble,’ resulting in rapid wear or seizure of the components, illustrating how seemingly minor clearances can lead to dire consequences.

Criticality of the issue:

Excessive clearance can significantly impact the engine’s structural integrity and performance. It leads to reduced oil retention within the bearings, causing increased friction and heat generation. Over time, this can result in rapid wear, overheating, and ultimately, engine failure. In extreme cases, it can cause the crankshaft to wobble or seize, potentially causing catastrophic damage to the engine and reducing its operational lifespan.

Components Involved & Their Role:

Main Bearings: These support the crankshaft, allowing it to rotate smoothly. They ensure proper lubrication and contribute to power transmission.

Crankshaft: The primary component responsible for converting the engine’s power into rotational motion. It interacts directly with the main bearings and operates under high stress.

Lubrication System: Provides the necessary oil to reduce friction between the bearings and the crankshaft, helping to maintain a smooth and efficient operation.

What Would Cause the Excessive Main Bearing Clearance ?

Wear and Tear: Over time, the bearings and crankshaft surfaces can degrade due to friction and inadequate lubrication.

Improper Installation: Incorrect fitting of bearings during assembly can lead to inconsistent clearances.

Oil Contamination: Contaminants in the oil can accelerate wear on the bearing surfaces.

Heat Damage: Excessive operating temperatures can cause materials to expand and wear down.

Engine Overhaul Errors: Inadequate or incorrect machining during rebuilding can result in poor tolerances.

- Poor Lubrication: Insufficient oil supply or low oil pressure can lead to rapid bearing wear.

Symptoms/Signs of the Excessive Main Bearing Clearance

Increased Engine Noise: A knocking or tapping sound may indicate excessive clearance.

Low Oil Pressure: Symptoms of low oil pressure can be due to increased clearances allowing oil to bypass bearings.

Engine Vibration: Unusual vibrations may occur from imbalanced crankshaft rotation.

Oil Discoloration: Dark or dirty oil can indicate contamination or excessive wear.

Metal Shavings in Oil: The presence of metallic debris signals significant bearing wear.

- Lube oil filter During filter cleaning observe for metal particulates

Consequences of the Excessive Crankcase Pressure

Piston Damage: High pressure can cause pistons to warp or crack.

Seal Failure: Excessive pressure often leads to gasket and seal blowouts.

Oil Filter Damage: Increased pressure can cause filters to rupture or clog.

- Crankshaft Damage: Prolonged excess pressure can lead to distortion and failure.

Troubleshooting and Actions to Be Taken in Case of Excessive Crankcase Pressure

Inspect Breather System: Check for blockages or malfunctions that could restrict airflow.

Check Oil Level and Quality: Ensure that oil levels are adequate and the fluid is not contaminated.

Test Piston Rings: Conduct a compression test to assess the condition of the rings.

- Monitor Engine Temperature: Ensure that the temperature is within safe limits to avoid expansion-related issues.

How to Address High Crankcase Pressure

1. Regular Engine Inspections: Conduct frequent inspections of vital engine components such as piston rings, valves, and seals. Regular checks ensure early detection of wear or damage, preventing the buildup of excessive crankcase pressure.

2. Breather System Maintenance: Ensure the breather system is clean and functioning properly. Blockages or malfunctions in the system can lead to pressure buildup, so timely cleaning and maintenance are essential for optimal performance.

3. Addressing Wear and Tear: Replacing worn-out components, such as piston rings and seals, is crucial to prevent pressure leaks. Operating with damaged parts can lead to excessive crankcase pressure and increase the risk of engine failure. We offer detailed inspection services and Main Engine Repair services to identify wear and tear, along with repair solutions to address any issues detected during the inspection. Additionally, we provide genuine Main Engine Spare Parts to ensure reliable replacement of worn components, enhancing engine performance and longevity.

4. Addressing Wear and Tear: Replacing worn-out components, such as piston rings and seals, is crucial to prevent pressure leaks. Operating with damaged parts can lead to excessive crankcase pressure and increase the risk of engine failure. We offer detailed inspection services and Main Engine Repair services to identify wear and tear, along with repair solutions to address any issues detected during the inspection. Additionally, we provide genuine Main Engine Spare Parts to ensure reliable replacement of worn components, enhancing engine performance and longevity.

5. Regular Breather Valve Checks: Inspect and replace breather valves when needed to ensure they are operating correctly.

Precautionary Measures for Addressing Excessive Crankcase Pressure

Routine Maintenance: Regular oil changes and inspections can prevent excessive pressure developments.

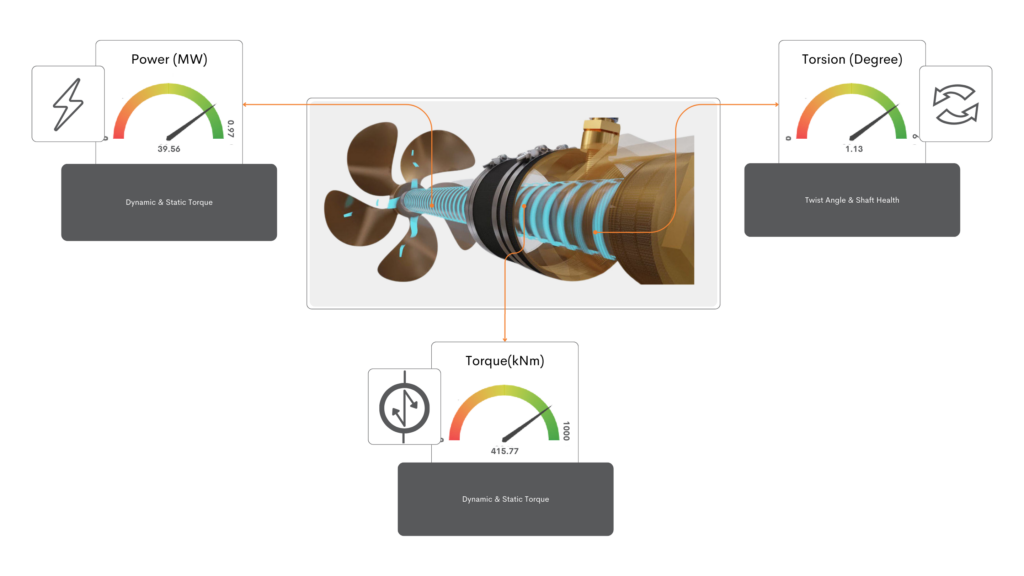

Monitor Engine Parameters: Use monitoring systems to keep track of pressure, temperature, and oil levels.

Training Personnel: Ensure that crew members are educated on the importance of proper engine operation and maintenance techniques.

Remote Monitoring: Deploy advanced remote condition monitoring systems to identify changes in bearing performance. Our cutting-edge Engine Condition Monitoring System, Vib360, offers early detection of engine faults, helping minimize maintenance expenses and avoid costly breakdowns.