Steam Turbines: Optimising Turbine Performance: Using Torsional Vibration Monitoring via VIB 360

Problem Statement

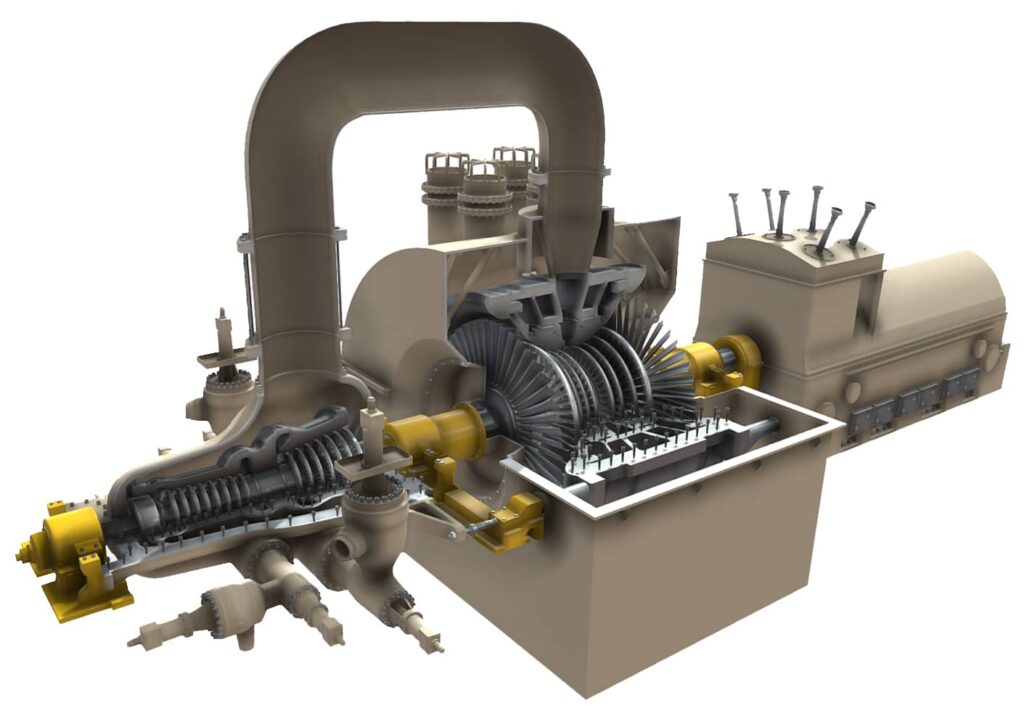

A power generation facility was facing recurring mechanical failures in its steam turbine, resulting in substantial downtime and revenue loss. The turbine, crucial for energy production, frequently experienced high vibration levels and unexpected shutdowns. Initial diagnostics pointed towards excessive torsional vibrations, but the exact source of the problem remained unclear. The displacement detected around the coupling-side bearing, which had an unusually high failure rate, was particularly concerning. The maintenance team could not identify the root cause, leading to increased operational costs, frequent repairs, and decreased overall efficiency.

Upon the plant team’s request, Impedance Data VIB installed the VIB 360 Turbine Condition Monitoring System to continuously monitor the turbine’s operational behavior. Unlike conventional systems, the VIB 360 system provides early-stage detection with high-precision analysis. Using MPU sensors, the system captured data across a broad frequency range, spanning multiple rotational speeds.

The VIB 360 system was equipped to detect misalignment, imbalance, and resonance—all potential causes of excessive torsional vibrations. By continuously monitoring the turbine’s behavior, the system pinpointed areas of excessive displacement and correlated them with specific operational loads and cycles. This allowed the team to identify vibration spikes occurring under specific operating conditions, which were directly linked to a misalignment at the coupling-side bearing.

Final Impact

The VIB 360 system enabled the power generation facility to pinpoint the exact cause of the excessive vibrations: misalignment at the coupling-side bearing, worsened by operational stresses. Based on the system’s real-time data and recommendations, the facility took immediate corrective actions, including realigning the bearing and redistributing the load.

The results were significant:

- Vibration levels were dramatically reduced, minimizing the risk of unexpected turbine failures.

- Over the next six months, the facility experienced a 40% reduction in turbine downtime, leading to a marked improvement in operational efficiency.

- Maintenance costs were reduced by 25%, as the need for frequent repairs was mitigated.

- The turbine’s operational lifespan was extended, offering both short- and long-term financial benefits.

The VIB 360 system continues to monitor the turbine, ensuring that it operates in optimal condition, providing ongoing insights for the maintenance team, and preventing future disruptions.

Conclusion

The installation of the VIB 360 Turbine Condition Monitoring System successfully resolved the issue of excessive vibrations, transforming a recurring problem into a manageable situation. The early detection and precise identification of the root cause led to substantial operational and financial gains for the facility. This case highlights the critical importance of continuous, high-precision monitoring in maintaining turbine health and efficiency.