Gas turbine condition monitoring system is a cutting-edge technology that measures Instaneous angular speed (IAS) to enable early-stage prediction of turbine health much earlier than other systems. Conventional systems are complex and use several accelerometers to monitor the health of the turbine but it does not prevent failure.

How Does it Work?

The system uses any one of the redundant speed sensors mounted by the OEM on the turbine. No other installation is required.

What Sets It Apart?

It Asses Emerging Fault

It helps to take proactive action as compared to current systems, which work to protect assets against damage.

Uses an Existing Redundant Sensor

This monitoring solution can be used with any Turbine, regardless of the make or model, making it a versatile and adaptable solution.

Direct (and therefore early) Measurement

Any abnormality in the turbine first affects the IAS of the rotating shaft. This is picked up by the MPU. current systems indirectly measure faults

Data Processing Is Done On Edge

All Analysis of the data is done in the customer environment. Monitoring of this data can be done In-situ as well as Remotely

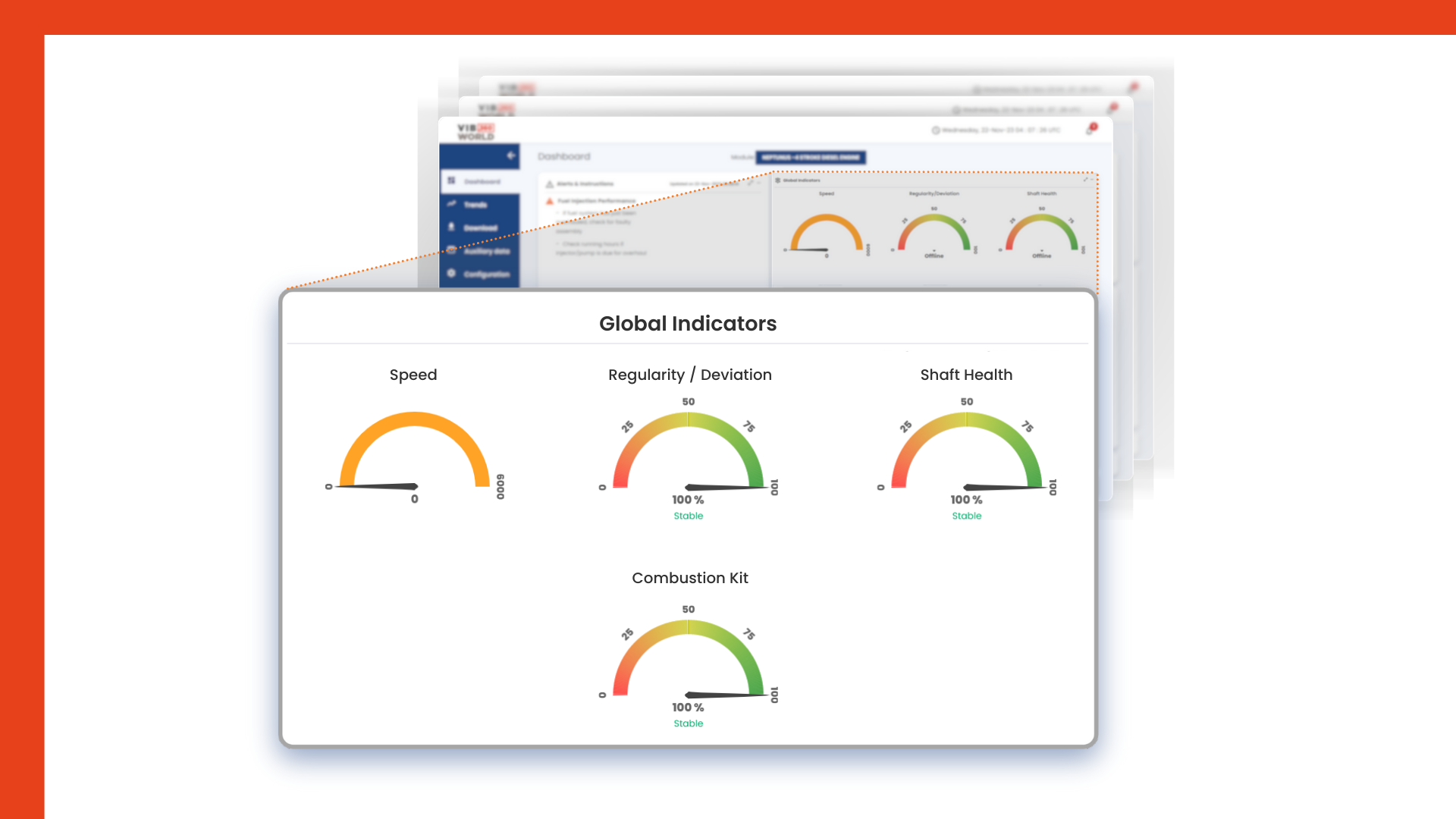

Key Features of our Turbine Condition Monitoring System

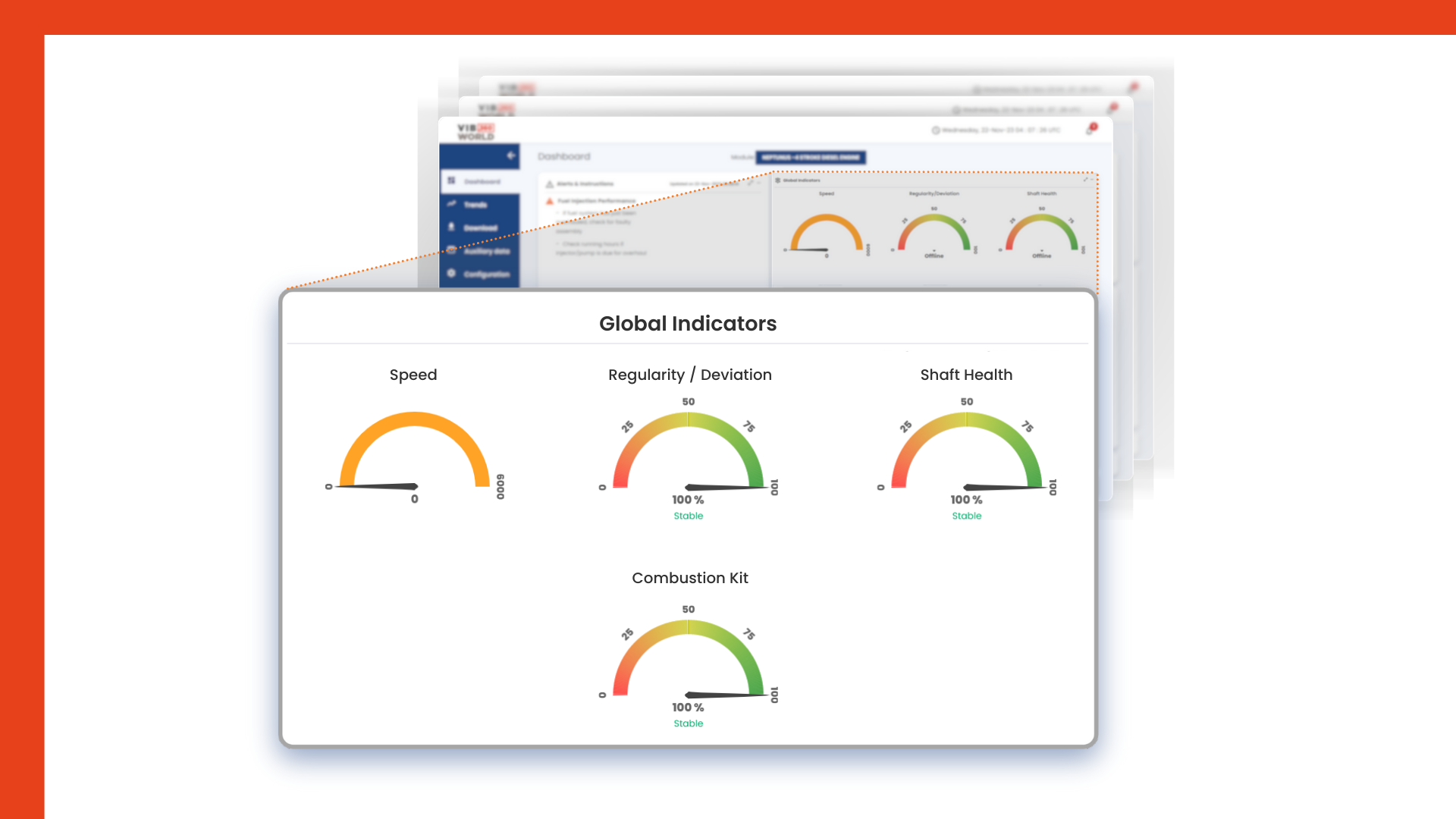

Health indicators for the Turbine

- Shaft Speed (RPM of shaft)

- Shaft health (Dynamic state of the shaft - include instability / erosion or damages to the blades.)

- Regulations / Deviations (Deviation in Speed)

- Mis alignment (Misalignment in Turbine and attached gearbox)

- Bearing health (shockss experienced / frictional loss in Journal bearings)

- Combustion Kit (Quality of Injection and combustion -incase of Gas Turbines)

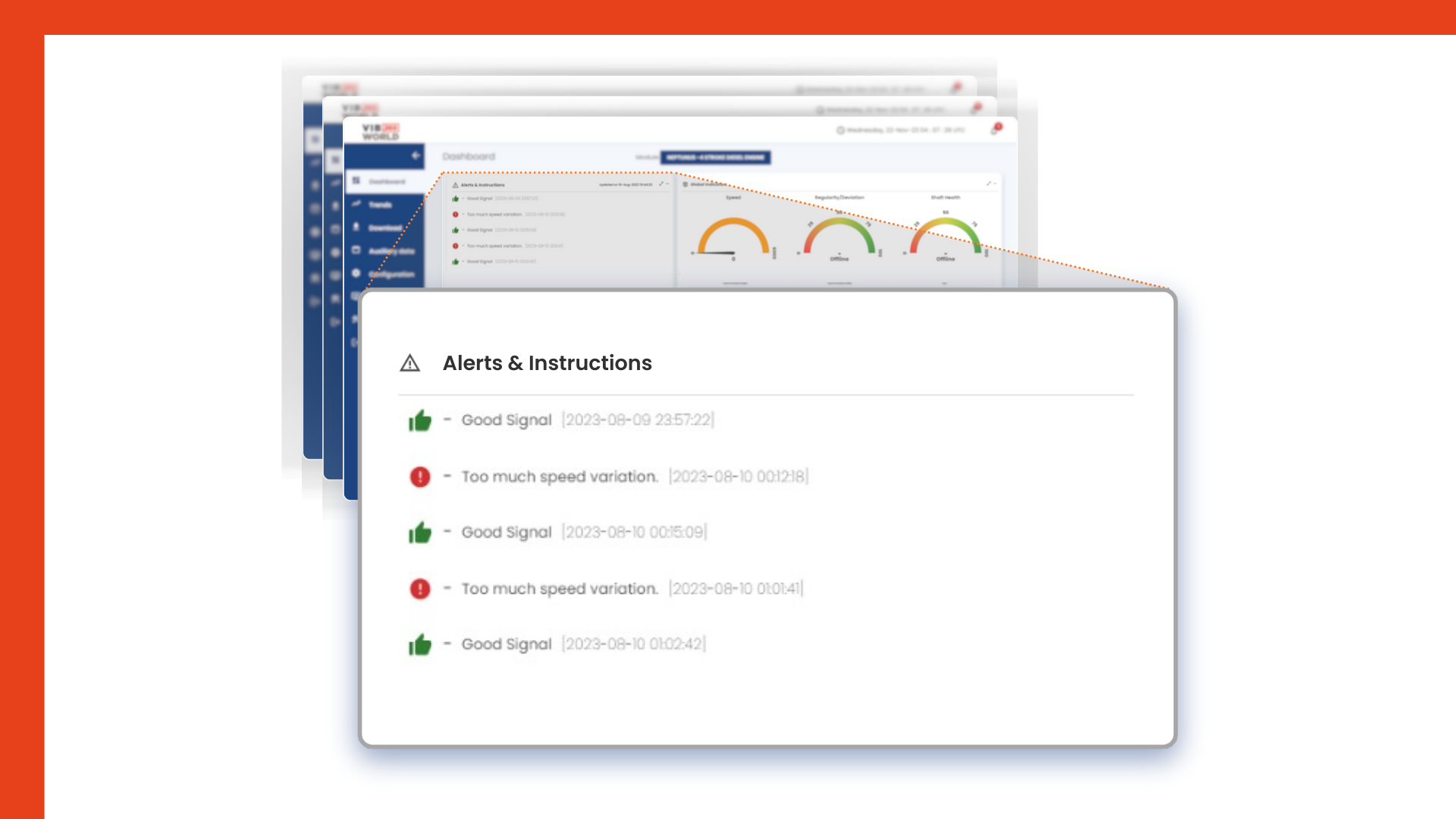

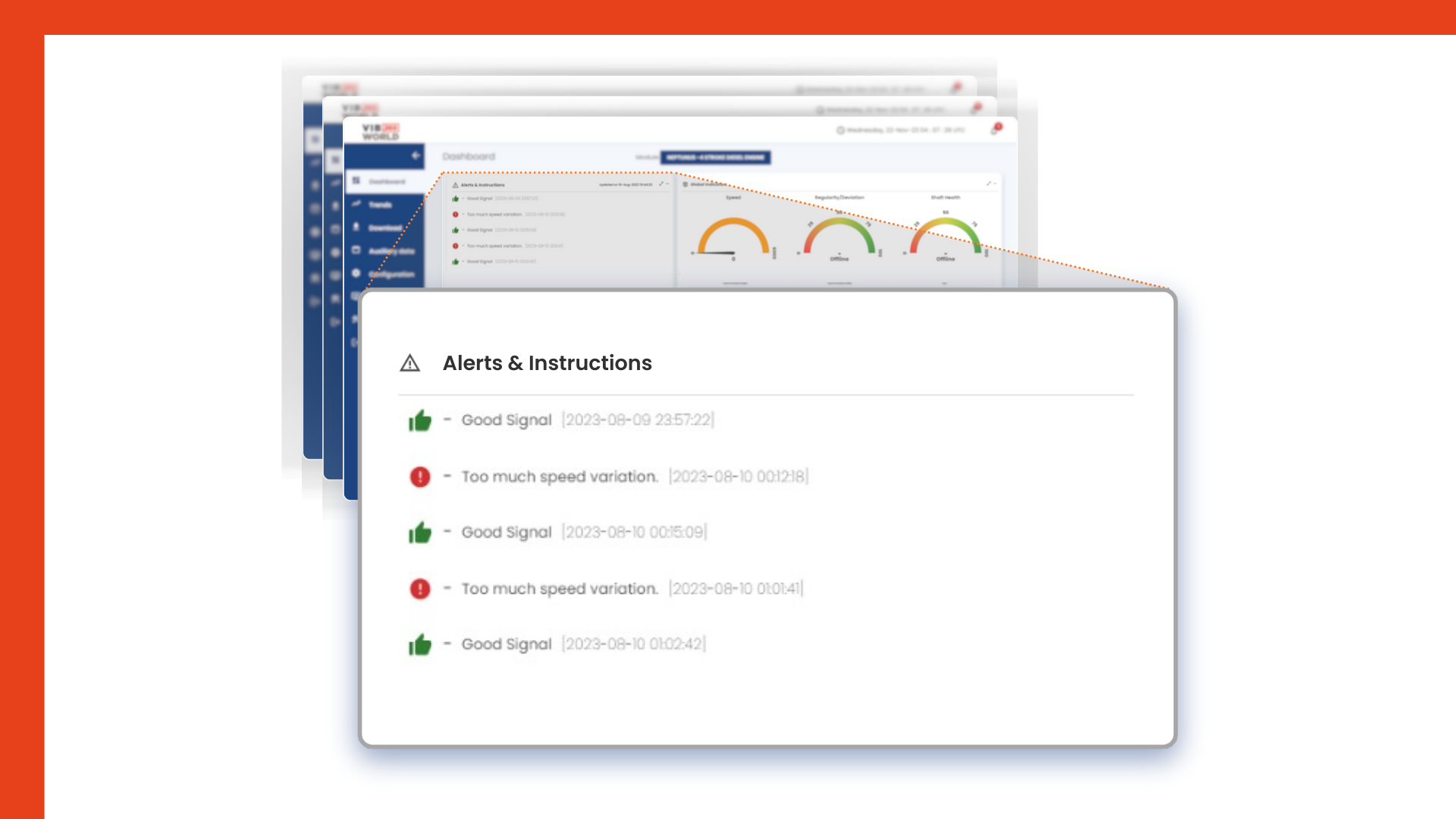

Alerts & Instructions

- Red Triangle: Indicates exercising caution and watching related engine operation closely (pre-alert conditions)

- Red circle: Indicates the alert condition. You may need to understand the operating condition better if you need minor intervention or troubleshooting if the trend/engine dynamic behavior persists irrespective of load conditions.

This information is a summary of recommended actions based on the nature of the operation for the operator to either be aware of or to act.

Notes:

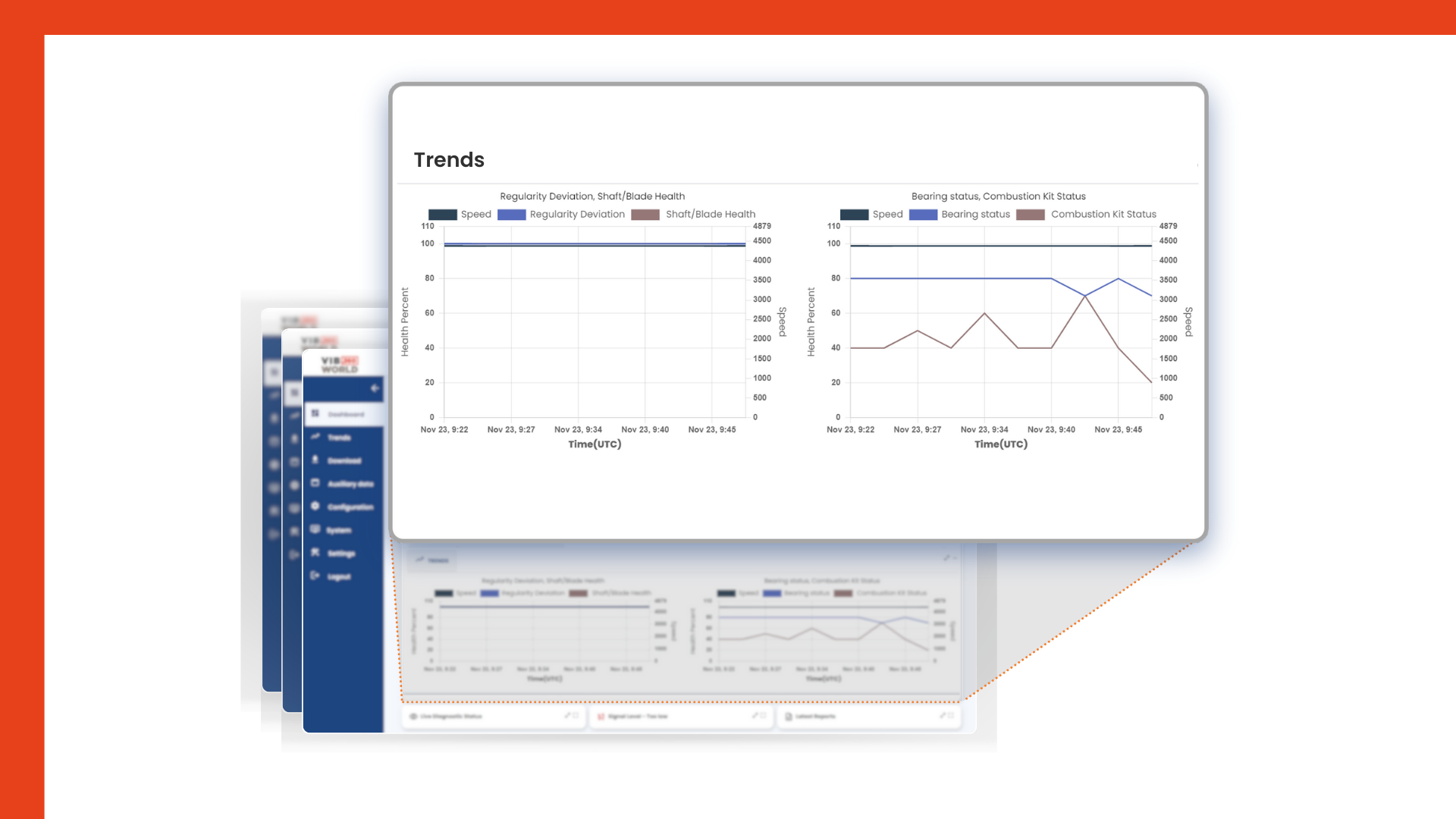

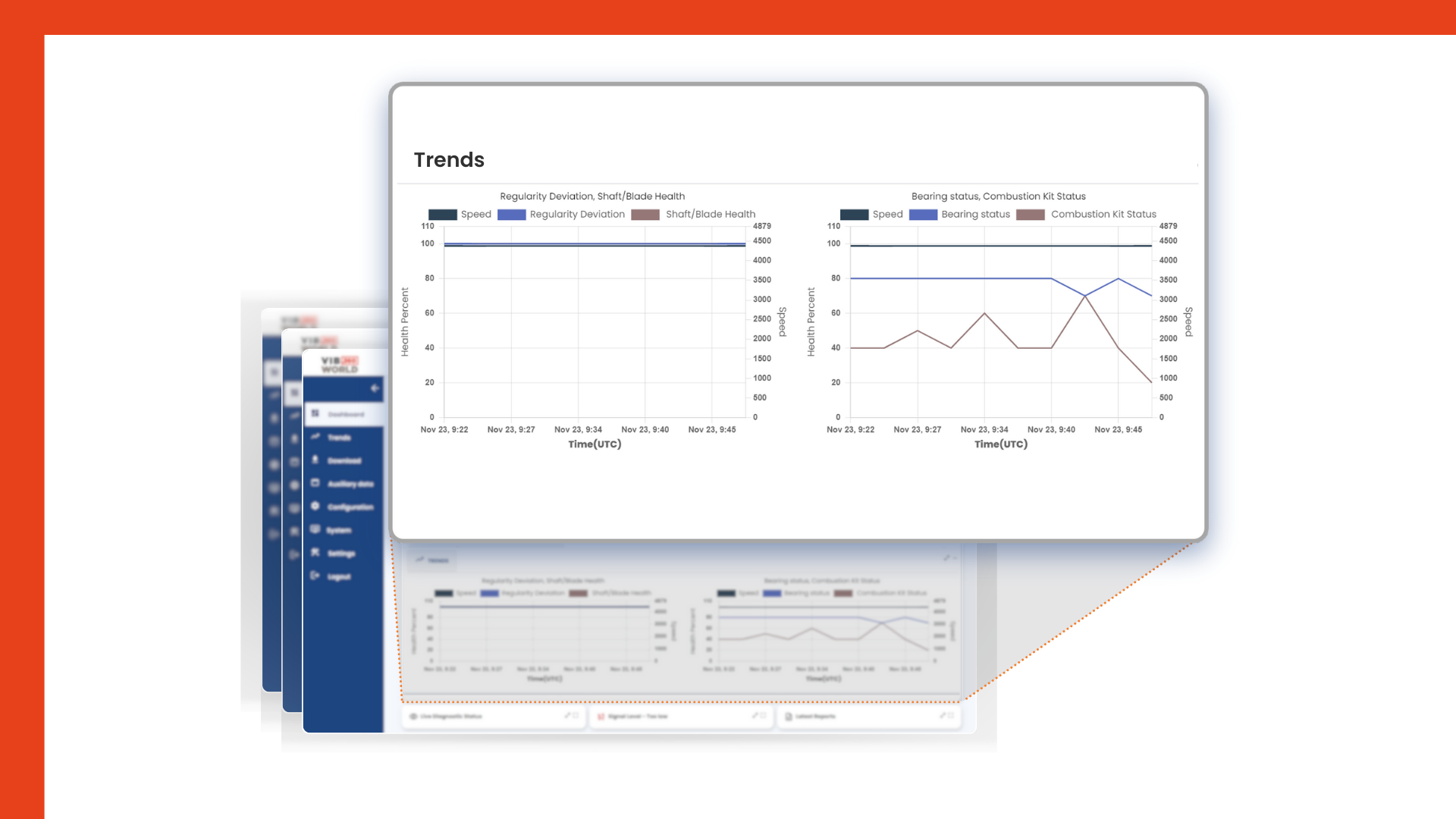

Trends

- The Trends tab draws long-term trends (approximately 3- months) for different indicators in the required combinations.

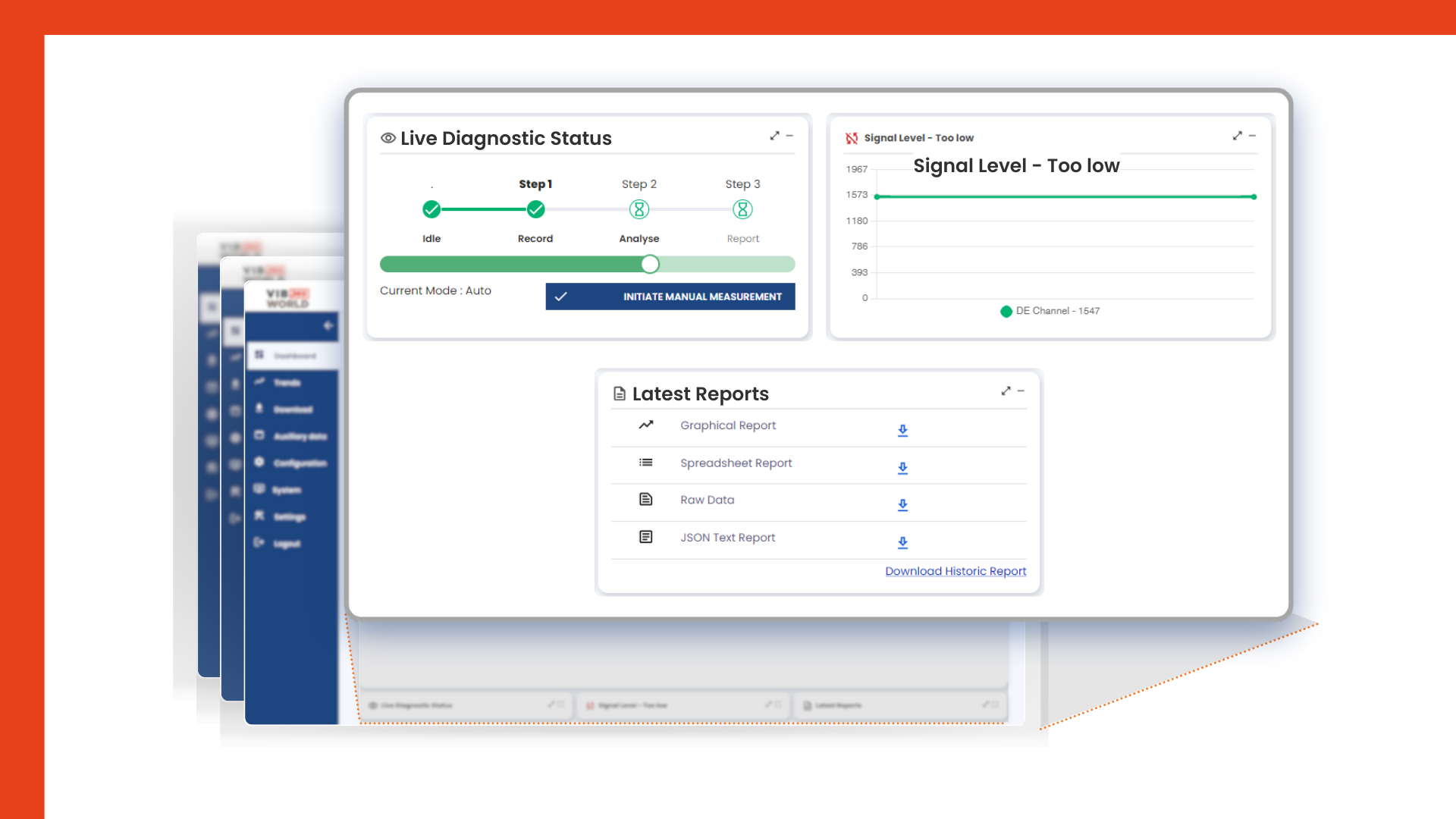

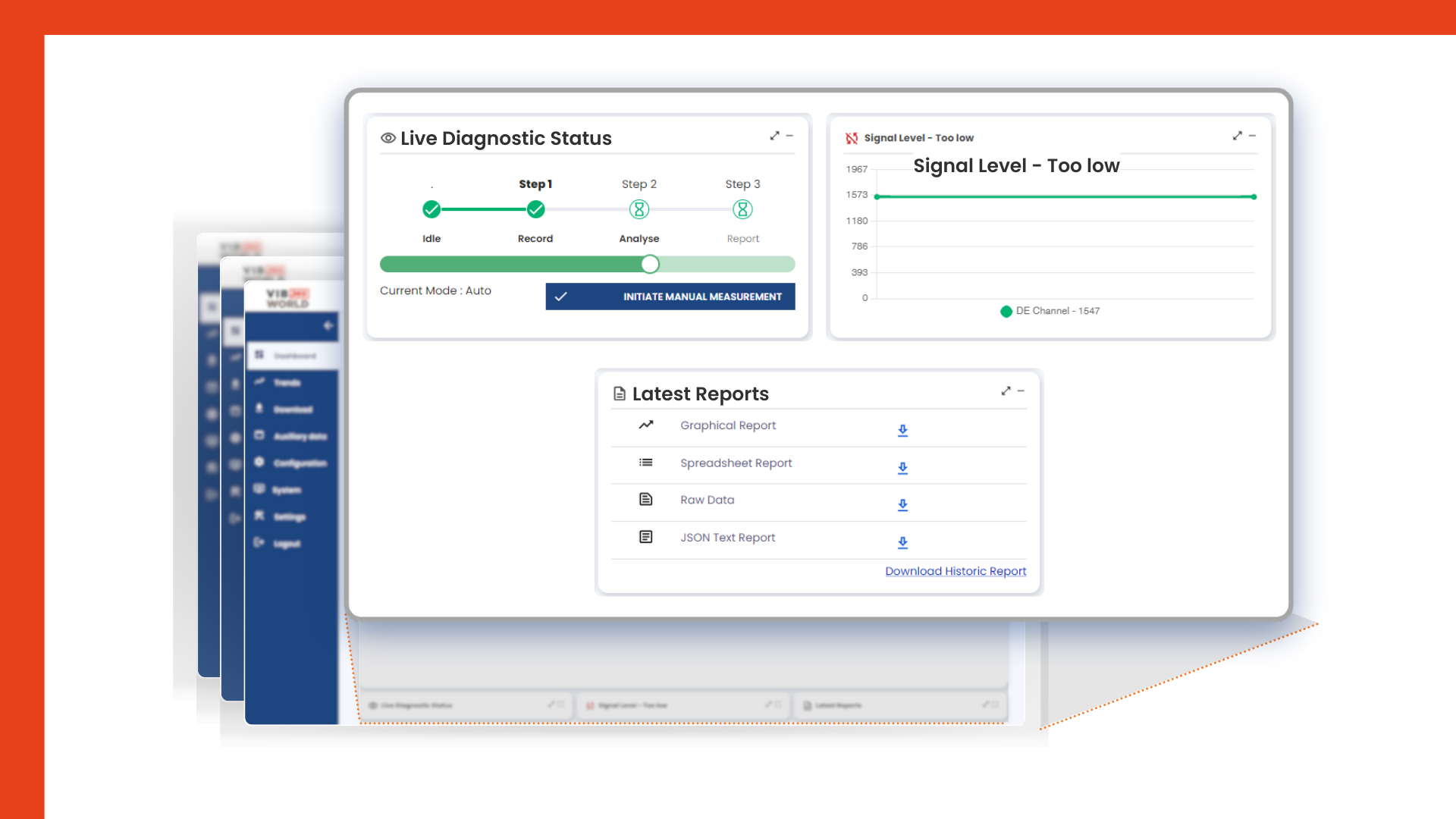

Live Diagnostic Status :

It indicates the processor status when processing the input right from data recording.

Signal Status:

It indicates synchronization information between two sensors when needed

Latest Reports:

The last processed Report can be downloaded in different formats such as Graphic, Spreadsheet, Raw Data, and JSON text as seen below. For extensive downloading one can visit the “downloading” tab from the side bar.